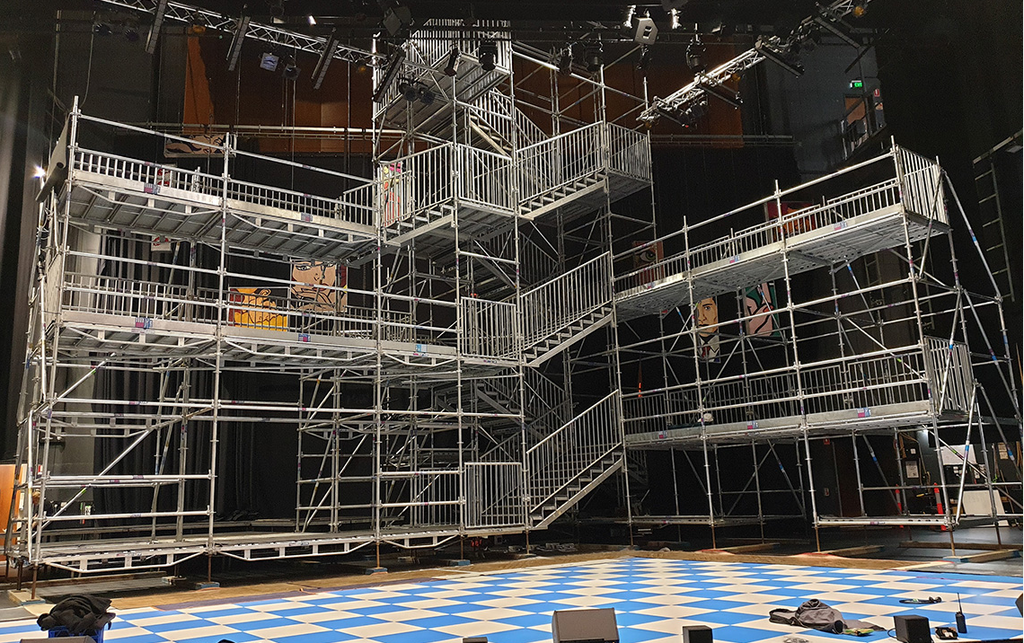

When it comes to working at heights, safety is the utmost priority. Any negligence or carelessness can lead to disastrous consequences. Scaffolding is a common method of working at heights, but it comes with its own set of risks. Therefore, it is crucial to follow strict safety protocols to ensure a safe work environment. In this blog, we will discuss some general scaffolding safety precautions that need to be followed for any scaffolding work.

-

Risk Assessment: A risk assessment must be conducted before starting any scaffolding work. It helps in identifying potential hazards and taking steps to minimize the risks. Factors like weather conditions, equipment, and worker's experience for the particular job should be considered while conducting a risk assessment.

-

Permit to Work: A permit-to-work system is mandatory before working at heights or using scaffolding. It is a formal authorization system that ensures all necessary safety protocols, including scaffolding safety protocol, are in place before starting the work.

-

Work at Height Training: All scaffolders must undergo proper training before starting any work at height. The training should cover topics like equipment handling, hazard identification, fall protection systems, and emergency response procedures.

-

Harnesses with a double Lanyard and 100% Tie-Off: The use of double lanyards and 100% tie-off must be strictly adhered to on worksites. It helps prevent falls and ensures scaffolding safety for your workers.

-

Competent Scaffolding Supervisors: A competent scaffolding supervisor must be appointed to oversee the work's critical task, including erecting scaffolding, ensuring worker's safety, and ensuring all safety protocols are in place.

-

Trained and Experienced Scaffolders: Only trained and experienced scaffolders should be hired to execute the task. They should also undergo regular training and refresher courses to keep their skills and scaffolding security knowledge up-to-date.

-

Inspection of Scaffolding Structure: A competent scaffolding inspector should conduct a weekly inspection of the scaffolding structure. Any damage or defects should be addressed immediately to ensure the safety of the workers.

-

Daily Toolbox Talk: Workers should be given daily toolbox talk to make them aware of the hazards related to work at height. It helps in ensuring they are following all necessary scaffolding safety protocols.

-

Visible Inspection Tags: Scaffolding should have visible inspection tags such as red, green, and yellow during erection, use, and dismantling. It helps in identifying the scaffolding's condition and any potential hazards.

-

Personal Protective Equipment (PPE): Suitable PPE such as hard hats, high visibility jackets, sturdy and non-skid safety shoes should be provided to all workers. It helps protect them from any falling objects or accidents.

-

Securing Tools: Workers should secure their tools and spanners with their body while working on scaffolding. It helps in preventing them from falling and causing any injuries.

-

Work Suspension: Scaffolding work should be suspended in the case of heavy wind or rain as it can be hazardous to workers. It is important to prioritize safety over work deadlines.

-

Dismantling Process: Scaffolding dismantling should start from the top and work downwards to prevent accidents. It is important to follow proper dismantling procedures to ensure scaffolding safety.

-

Brace and Tie-In Scaffolding: One of the most important scaffolding safety precautions when working at height is to ensure that the scaffolding is properly tied-in and braced. This prevents the scaffolding from toppling over and causing serious accidents. The tie-in process involves securing the scaffold to a building or other structure, while bracing involves adding diagonal supports to the scaffolding to give it extra stability. Both of these steps are critical for ensuring the safety of workers on the scaffold. The Proscaf system has a range of tie-in components and the Proscaf cross braces have the highest load ratings in the market.

-

Barricading and Signboards for Scaffolding Work: When scaffolding work is being carried out, it is important to cordon off the area to prevent unauthorized personnel from entering. This can be done using barricades, fencing or other physical barriers. Signboards should also be placed to indicate that work is in progress and to warn people of the potential hazards. These measures help to prevent accidents and ensure the safety of both workers and members of the public.

-

Regular Inspection and Maintenance of Scaffolding: It is important to ensure that scaffolding is inspected regularly to ensure that it is safe to use. This involves renewing the scaffolding tag every week, which indicates that the scaffold has been checked and is safe to use. A checklist should also be maintained to ensure that all necessary safety precautions have been taken, such as checking that the scaffolding is properly tied-in and braced, that workers are using appropriate PPE, and that tools and materials are properly secured. Regular inspections and maintenance help to ensure the ongoing scaffolding safety and prevent accidents from occurring.

- Pre-Inspection Checks: Finally, before commencing any work at height, it is essential to conduct pre-inspection checks to ensure the safe access of the scaffolding. This check includes inspecting the foundation, base plates, bracing, tie-ins, and platform's condition. Any issues must be addressed before proceeding with the work.

In conclusion, it is critical to ensure that proper safety precautions are taken when using scaffolding. From conducting pre-inspection checks to providing appropriate training and PPE, every step must be taken to minimize the risk of accidents and keep workers safe. By following the scaffolding safety guidelines outlined above and adhering to strict safety protocols, we can ensure that work at height can be carried out safely and effectively, providing a secure and efficient environment for workers to carry out their duties with confidence. Remember, safety should always come first.